Chemispray

General Description

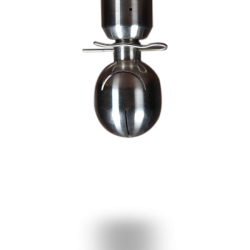

“Washmatics” Tankwasher model ChemiSpray series consist of ChemiSpray 25, 75 & 100 in PTFE or C‐PTFE

construction. These washers are ideal for applications where the cleaning fluid is corrosive to stainless steel.

The disc rotates friction free on hydraulic bearing instantly creating washing liquid droplet spheres with

powerful spray impingement most suitable for burst rinsing

Applications

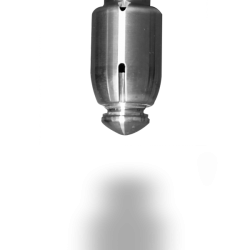

These washers are suitable for cleaning small/ medium process vessels, storage tanks..Ideal for

applications where longer chemical dwell times for improve cleaning result is required.. Compact in design

these are suitable for wide range of industries including pharmaceutical and biotech industries, nuclear as well

as for food & Beverage industries. Wide range of chemicals can be used as washing fluid due to material of

construction (MOC) of these washers being virgin PTFE or 25% carbon filled PTFE

Operations

“Washmetics” ChemiSpray Tankwasher is driven by wash liquid flowing through it at a suitable pressure and

flow rate. The disc rotates on wash liquid. Therefore it is necessary that the unit is supplied with wash liquid at

a correct pressure and flow rate for proper results. It is important that the specified pressure to be maintained

at washer inlet point.

Maintenance

These washers require no maintenance. However periodical visual inspection gives a long life. At site

dismantling or re‐fitting at site is not recommended